IOC 2025 Exhibition

About Us

Changsha Rui Rui Technology Co., Ltd., established in 2021 and certified as a National High-Tech Enterprise, is a innovative provider of software and services in the field of computational materials design. Our mission is to bridge the gap between materials science theory and industrial application through robust, user-friendly digital tools.

Our Technology and Software Suite

Our flagship achievement is the development of a complete digital workflow within the Integrated Computational Materials Engineering (ICME) framework. This platform connects calculations across multiple scales to establish the crucial “process-structure-property” linkage for metallic materials.

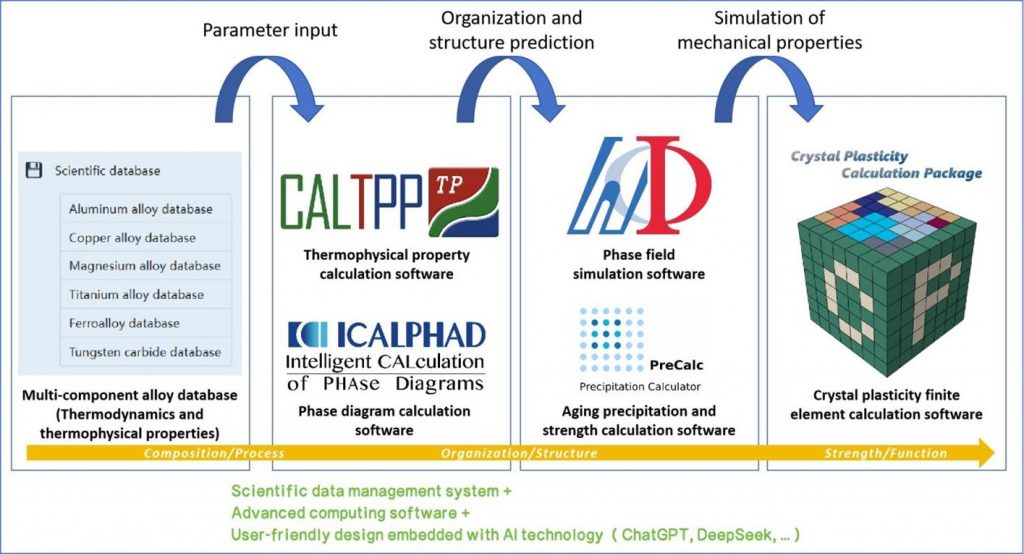

a digital workflow was developed based on the “microstructure-performance correlation”. It starts from scientific databases and integrates phase diagram thermodynamic calculation, thermophysical property calculation, phase field simulation, and crystal plasticity finite element calculation in sequence. For each computational stage, dedicated software tools were designed and developed. These developments focused not only on solving specific computational problems but also on ensuring theoretical connections and seamless data transfer between them, aiming to create a universal intelligent design platform for metallic structural materials, as depicted in Figure 1.

Figure. 1 ICME flowchart based on database and software

The digital workflow consists of several sequentially linked computational modules, each implemented through dedicated software tools. The software in the Fig. 1 is briefly introduced as follows:

ICALPHAD (Intelligent CALculation of PHAse Diagrams): A software tool based on the CALPHAD method for calculating phase diagrams and optimizing thermodynamic parameters of materials systems. It is used for predicting material properties and phase behavior in materials science and engineering. For more information, https://doi.org/10.1016/j.calphad.2025.102810.

CALTPP (CALculation of ThermoPhysical Properties): Provide various thermophysical properties such as diffusion coefficient, interfacial energy, thermal conductivity, viscosity. For more information, https://doi.org/10.1016/j.jmst.2019.12.005.

MID-MESO (Microstructure Intelligent Design MESOscale): An open-source phase-field solver package for simulating multiphase transformation and mechanical analysis of polycrystalline nanoparticles. For more information, https://github.com/Microstructure-Intelligent-Design.

PRECALC (PREcipitation CALCulator): A computational software for age-hardening materials, integrating functions such as age precipitation and macroscopic strength and electrical conductivity prediction. For more information, https://doi.org/10.1016/j.jmrt.2024.05.145.

CPCP (Crystal Plasticity Calculation Package): A research/teaching toolkit based on the crystal plastic finite element method. At present, it has successfully carried out calculation simulation on aluminum alloy, high-strength steel, cemented carbide, coating materials and so on. For more information, https://www.ams.org.cn/CN/10.11900/0412.1961.2024.00083.

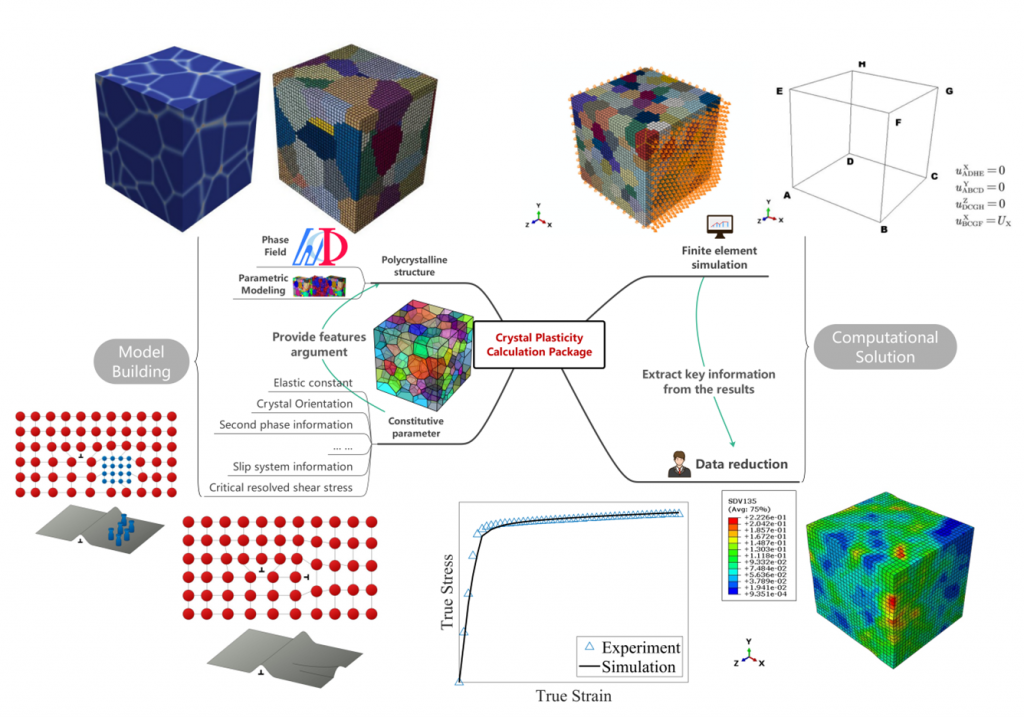

This series of software components involved in the workflow encompasses the transmission and circulation of various material information. Starting from the database, phase diagram information and thermophysical data of alloy materials at specified compositions and temperatures are obtained through ICALPHAD and CALTPP software, which supports the subsequent phase field simulation (MID-MESO) and precipitation prediction (PRECALC). After obtaining the exact state of the structure and microstructure, the mechanical property prediction under specified loads is conducted through crystal plasticity finite element software. Figure 2 shows the corresponding computational steps behind the combination of these software.

Figure. 2 Flowchart of crystal plasticity finite element calculation